You've reached the Virginia Cooperative Extension Newsletter Archive. These files cover more than ten years of newsletters posted on our old website (through April/May 2009), and are provided for historical purposes only. As such, they may contain out-of-date references and broken links.

To see our latest newsletters and current information, visit our website at http://www.ext.vt.edu/news/.

Newsletter Archive index: http://sites.ext.vt.edu/newsletter-archive/

The Cow/Calf Manager

Livestock Update, October 2000

John Hall, Extension Animal Scientist, Beef, Virginia Tech, and Rodney Leech, Extension Agent, Highland County

Good Facilities are a Key to Good Management

Over the course of a year, a beef producer or his veterinarian will need to perform many management tasks including vaccination, deworming, doctoring, pregnancy diagnosis and weaning. Having good facilities will make the job easier, faster and safer. Baxter Black once said There's gotta be an easier way to work cattle than with a lasso and an oak tree or clothesline and a yard dog Well-designed working facilities are the better way.

Location of the facility is very important. There should be easy access to the facility from most of the pastures as well as the road. Remember it's easier to move cattle than pull trucks out of the mud. Proximity to electricity and water is important also. The site should be well drained. Shade and some wind protection are a plus.

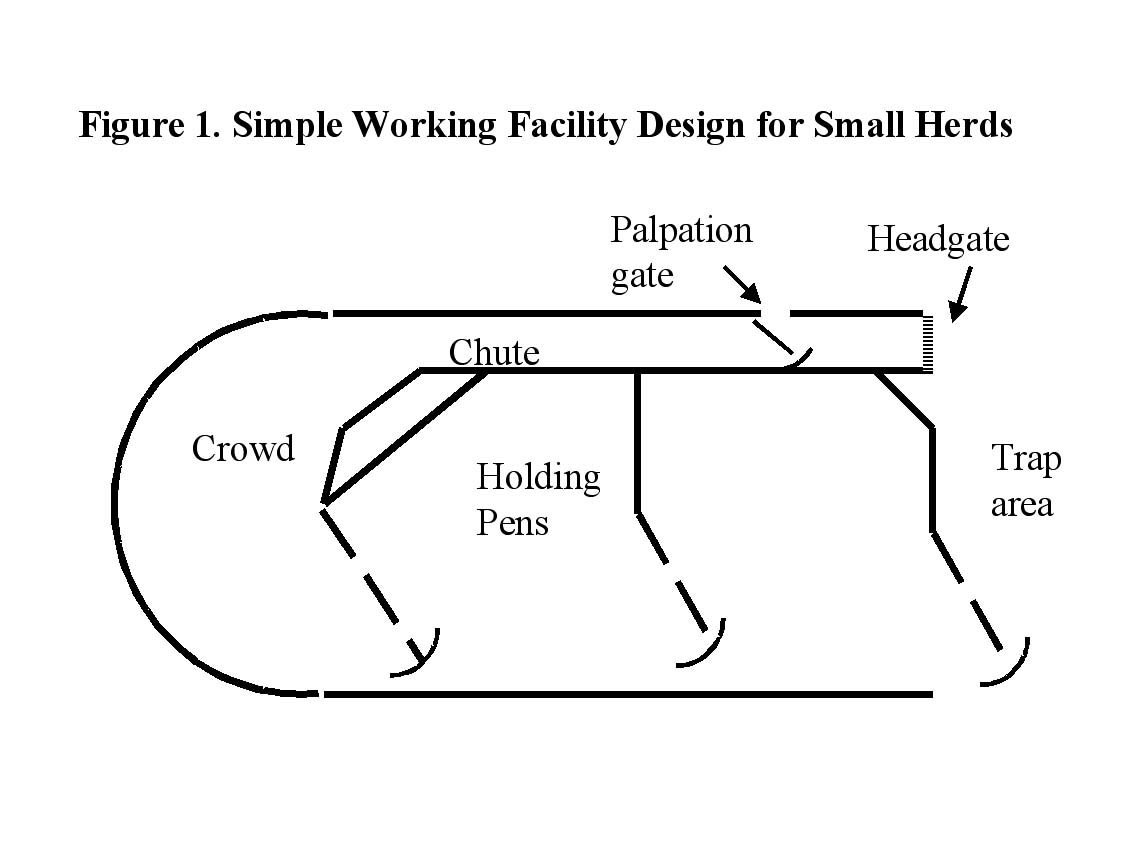

Whether you are making facilities from scratch or renovating and existing facility, working facilities need to have the basic components listed below. A diagram of a simple working facility for 30 to 40 cows is shown in Figure 1.The size of these components will depend on the size and number of cattle to be worked (Table 1).

Holding Pens -- These should be large enough to hold the entire herd or group of cattle at one time. Fences for holding pens should be at least 5' tall but do not need to be solid. Treated 2'x6' or 2'x8' boards or feedlot panels with rub-rails make good fences for holding pens. At least two holding pens should be built so cattle can be sorted easily if needed.

Crowding Area -- Also called a sweep tub in some designs. This area narrows from the holding pen to the chute. It is the area with a crowding gate that helps in moving cattle to the chute. The crowding area should have solid sides 5Ė high and the crowding gate should be solid as well. The crowd can be made out of wood or steel. The opening to the crowd and the crowd gate should be the same size usually 10' to 12'.

Working Chute -- The narrow solid sided alley that leads from the crowd to the headgate or squeeze chute. This makes the cattle follow one another single file. Blocking gates or pipes should be placed at the beginning of the chute and at 8' to 20' intervals to keep cattle from backing up. Often the chute is built too wide which allows animals to turn around or to get stuck trying to turn around. Pay close attention to the dimensions in Table 1.

Working Area / Headgate -- The area at the end of the chute where the animal is restrained to receive treatment or procedures. A roof over this area is a desirable option. In most operations, this area will include the headgate and blocking gate or pipe. In larger operations, a squeeze chute in addition to the headgate is desirable. The squeeze chute allows the animal to be fully restrained by holding or squeezing the sides of the animal. Some local cattleman's associations have a portable squeeze chute for use by their members.

Palpation Gate -- A small gate in the working chute about 8 to 10 before the headgate that allows access to the rear of the animal. Palpation gates are essential for pregnancy checking, artificial insemination and treating rear foot problems. It should block the chute to prevent the next animal from pushing against the animal in the working area or injuring the person working at the rear of the cow.

Loading Chute -- Usually a separate chute or gate for loading and unloading cattle. The ramp height should accommodate the type of truck or trailer used most (Table 2). An adjustable height loading chute is ideal in most moderate to large operations. In small operations, the head gate area often doubles as the loading chute for trailers.

Trap -- An area of 1/4 to 1 or 2 acres around the working facility that is connected to the holding pens. The entrance to the trap is large usually 20 to 32 and is usually a wire gate or double gate. This allows cattle to flow in easily without feeling too confined when coming from the main pasture. This area is often left off of eastern working facilities, which is a big mistake! The trap also acts as a safety area if cattle get out of the working facility or accidentally are let go from the headgate. Too many times I have seen folks bring cattle into a working facility without a trap on the edge of a 100-acre boundary only to have a few get loose and wreck the day.

Scales -- These are often thought of as an option, but more cattlemen need to think of them as a must have item. Electronic scales are expensive, but are good for large operations due to their speed of weighing. Often, good used beam scales can be found at farm auctions. Many local cattlemanĖs associations or Extension Agents have access to portable scales.

The cost of facilities will vary too. Using local rough cut lumber, cedar or locust posts and a used manual headgate a good facility can be assembled for $ 500 or less plus a lot of sweat equity. On the other hand, complete pre-fabricated metal facilities with squeeze chutes can cost well over $10,000 setup. Headgate range from $200-$300 for manual types to $300-$600 for self catching types. Squeeze chutes generally cost from $1500 to $3000.

For help with designing or information on facilities contact your local Animal Science Extension Agent, Agricultural engineer or handling equipment sales professional.

Table 1. Dimensions for working facilities

| Size of animals to be worked | |||

| Area | Up to 600 lbs. | 800 to 1200 lbs. | Over 1200 lbs. or Cow-Calf |

| Holding, sq ft/head | 14 | 17 | 20 |

| Crowding, sq ft/head | 6 | 10 | 12 |

| Working Chute (vertical sides), width | 18 | 26 | 28 |

| Working Chute, length | 20 | 20 | 20-30 |

| Loading Chute, width | 26 | 26 | 28-30 |

| Corral fence height, min. | 60 | 60 | 60 |

Table 2. Loading chute heights for different vehicles

| Vehicle | Stock Trailer | Pickup | Stock Truck | Tractor-Trailer | Double Deck Trailer (no inside ramp) |

| Ramp Height | 0-15 | 28 | 40 | 48 | 100 |

Some good resources on Working Facilities are:

Books

Websites

![]()

Visit

Virginia Cooperative Extension