You've reached the Virginia Cooperative Extension Newsletter Archive. These files cover more than ten years of newsletters posted on our old website (through April/May 2009), and are provided for historical purposes only. As such, they may contain out-of-date references and broken links.

To see our latest newsletters and current information, visit our website at http://www.ext.vt.edu/news/.

Newsletter Archive index: http://sites.ext.vt.edu/newsletter-archive/

Viticulture Notes

Vineyard and Winery Information Series:

Vol. 19 No. 5, October-November 2004

Dr. Tony K. Wolf, Viticulture Extension Specialist

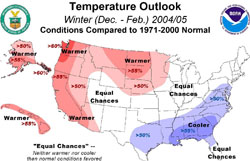

We've had two pretty tough years in a row, as have many of our co-horts in Pennsylvania and the Finger Lakes. It would be comforting to hear that 2005 will reverse this trend. Of that I'm not certain. I am certain though that we must first traverse winter, and NOAA is predicting that the resurgence of El Niño will usher in a colder and perhaps stormier winter than usual for the SE US (see Figure 1 from NOAA).

Below average temperatures are expected across the Gulf Coast states, the Southeast and the mid-Atlantic region of the U.S. (http://www.noaanews.noaa.gov/stories2004/s2326.htm). Vines are affected by extremes of cold and "below-average" may be most acutely noticed by home heating bills in the face of increased energy costs. On the other hand, it might be wise to hill-up graft unions this fall, just in case. See my Viticulture Notes from this time last year for a review of rationale and methods of hilling (http://www.ext.vt.edu/news/periodicals/viticulture/03septemberoctober/03septemberoctober.html). Mark Chien, grape extension agent in SE Pennsylvania, also has a discussion of hilling and dehilling of graft unions that you can obtain directly from Mark (mlc12@psu.edu).

Return to Table of Contents

Application rates from pre-bloom forward are at 150 gallons per acre (we have a small vineyard and can afford to use a lot of water). Spray adjuvants are not generally used and most of the products are used at a higher or highest rate when a range of rates is specified on the label. Vines are primarily vinifera (Chardonnay, Cab franc, Viognier), so an intensive spray program for mildew control is used.

Table 1. Fungicides and insecticides, and stage of growth at each application, used in the AHS AREC research vineyard during 2004. "Precp." Is the amount of rainfall (inches) that was recorded since the last spray (e.g., 1.30 inches of rain was measured between 7 and 17 May).

| Date | Pesticides used | Growth stage | Precp |

|---|---|---|---|

| 27 April | Penncozeb 75DF, Nova 40W, Microthiol Disperss (sulfur) | 3-5" shoots | |

| 7 May | Penncozeb 75DF, Microthiol Disperss (sulfur) | 6-8" shoots | 0.4 |

| 17 May | ProPhyt, Elite 45DF, Microthiol Disperss (sulfur) | 16-36" shoots | 1.3 |

| 21 May | Ridomil Gold MZ, Elite 45DF, Microthiol Disperss (sulfur) | pre-bloom | 0.5 |

| 28 May | Pristine, Microthiol Disperss (sulfur) | bloom | 0.8 |

| 10 June | ProPhyt, Elite 45DF, Microthiol Disperss (sulfur) | post-bloom | 1.8 |

| 25 June | Penncozeb 75DF, Imidan 70W, Microthiol Disperss (sulfur), Vangard WG | cluster closing | 1.9 |

| 6 July | ProPhyt, Elite 45DF, Imidan 70W | berries hard & green | 1.9 |

| 20 July | Abound, Imidan 70W, Microthiol Disperss (sulfur) | berries hard & green | 2.8 |

| 4 Aug | Pristine | veraison | 0.8 |

| 20 Aug | ProPhyt, Elite 45DF | veraison | 1.8 |

| 10 Sept | ProPhyt, Captan 50WP | berries not quite ripe | 4.6 |

| 29 Sept | ProPhyt | Berries still (!) not quite ripe | 7.9 |

What did we do differently in 2004? Our program was essentially based on a 10-day (±) program in the pre- to immediate post-bloom period, extended somewhat after the first of July. Summer rainfall was average (June-July), below average (May and August) or above average (September). We used sulfur (3 or 4 lbs/acre) in every spray through June, as well as one spray in late-July, this to help slow the appearance of strains of powdery mildew (PM) having resistance to sterol-inhibiting (e.g., Elite) or strobilurin fungicides. Our last PM fungicide was applied on 20 August. We saw no evidence of PM on fruit and only began to see an occasional foliar lesion in October and those lesions failed to make significant progress. We relied more heavily on phosphorous acid (ProPhyt) for downy mildew control this year than in 2003. As has been reported by others in the region, we too correlated the use of phosphorous acid with some leaf burning more of a concentrated stippling on the upper leaf surface than the clear zones of necrosis caused by sulfur burn. We felt that the apparent phytotoxicity which we attributed to phosphorous acid was tolerable. Compared to 2003 (a wetter year), we relied less on strobilurins, and more on sulfur and phosphorous acid, although we still used more sterol-inhibitor (Elite) than desired. I do not know for certain that Elite is still fully effective for PM in our vineyard, nor do I have evidence that it is not. Even if it were, it still provides black rot control. The September application of captan prophylactically targeted bitter rot and ripe rot. Our most significant disease issue was foliar downy mildew (DM) which had toasted about 5 to 10% of the leaf area on some vines by October. I doubt that the DM had a serious impact on fruit maturation but > 10 inches of rain in September probably did. Nevertheless, we harvested Cab franc the week of 11 October at 22.5 to 23° Brix. The Imidan sprays in late-June and July principally targeted Japanese beetles, but may have also controlled grape berry moth which we scouted for but gratefully did not find in significant numbers. From a materials standpoint, the 2004 fungicide and insecticide program totaled about $450 per acre. The spray program for Chardonnay which we use in the current vineyard economic budget projects a fungicide and insecticide cost of about $460/acre, so we do not feel that the 2004 season was out of line. We have altered our weed control program over the past two years, relying more on an early-season post-emergence herbicide, then allowing weed growth (mostly crab grass) from July forward. We purchased a hand-held sickle-bar mower (Stihl) this year which we use for under-the-trellis weed trimming and for shoot hedging.

Return to Table of Contents

Defining a thermal environment for high grape and wine quality: Erl Happ is a self-taught wine-maker from Western Australia. In addition to his knowledge of wines, Erl has deeply examined the climatic basis of wine quality, paying particular attention to how temperature impacts fruit and wine quality. Erl published a series of papers in The Australian and New Zealand Wine Industry Journal (see references which follow) that advanced a thesis that the best wines in the world are produced in regions that accumulate less than 500 degree-hours above a base temperature of 22°C (72°F) in the last month before harvest. Erl further asserts that this threshold temperature summation applies across most, if not all, varieties. Erl's first presentation at the ASEV-ES symposium went into the details of how he arrived at this conclusion. As a starting point, Erl's data are generated from hourly temperature observations, rather than the more commonly used daily mean temperatures. An underlying argument is that hourly summations give a more accurate picture of the thermal regime a grape experiences than do daily mean (high+low/2) summations. Erl uses temperature loggers that record hourly temperature on site. The data are downloaded to an Excel datasheet. Hourly observations that exceed 22C generate a heatload for that hour which is the degree difference between the observation and 22. For example, if the hourly temperature is 28C, then the heatload for that hour is 6 (28-22=6). The value for that hour is summed with all other values for the period of interest (e.g., the last 28 days prior to harvest). Erl applied this method to many of the world's most recognized wine producing locations and surmised that locations that sum to no more than about 500 hourly heat units in excess of 22C in the last month before harvest tend to have greater quality recognition than those that exceed this threshold. Why? Erl believes that temperatures in excess of 22C during fruit maturation are counter-productive to flavor and aroma retention in the ripening grapes. The threshold temperature of 22 and the accumulated sum of 500 in the month before harvest can be debated, but we aim to explore Erl's thesis in the mid-Atlantic using data that have been collected over the past several years and which will be collected in the future. We will again be seeking hourly temperature data from interested cooperators to further pursue this model.

References:

Happ, E. 1999. Indices for exploring the relationship between temperature and grape and wine flavour. The Australian and New Zealand Wine Industry Journal 14:68-75.

Happ, E. 2000. Site and varietal choices for full flavor outcomes in a warm continent. The Australian and New Zealand Wine Industry Journal 15:1-7.

Soil and climate contributions to grape potential: Cornelis (Kees) van Leeuwen is a viticulturist with Bordeaux Agricultural University. Kees is also the viticulturist for Cheval Blanc in Bordeaux where we had originally met during a study tour of France in December 2002 (http://www.fst.vt.edu/extension/enology/France/France2002.html). Kees is well qualified to discuss the relationship between soil quality and wine quality, particularly as soil moisture relates to wine quality. His first discussion at the symposium outlined what he considered the important determinants of wine quality from the standpoint of grape "potential." These attributes included small berries, high concentration of 'ripe' phenolics in the berry skin and seeds, excellent varietal flavors, low malic acid levels, and absence of vegetative characters. The fruit must be healthy to achieve these attributes (absence of rot, sunburn, physiological disorders, etc.). We might say that this is intuitively obvious; however, we still have significant challenges obtaining such fruit under our ripening conditions in the mid-Atlantic. Kees's discussion went on to describe methods used to increase grape potential, starting by restricting vine vigor. Vigor indices were reviewed to compare relatively high vigor vines with relatively low vigor vines, the latter being preferred. How can vigor be restricted? Options include low vigor rootstocks (e.g., Riparia Gloire de Montpellier), choosing soils that have low water-holding capacities, and selecting clones that express small berries. Much of Kees' first discussion described an 8-year study in Bordeaux of factors that affected wine quality. Key points from this discussion were that vintage (year-to-year climatic variation) has a predominant effect on cessation of shoot growth and onset of veraison, whereas soil (moisture-holding capacity) has a more significant effect on berry size (also affected by vintage and cultivar). Soil also affects berry sugar and skin color, but indirectly, whereas the vintage exerts a greater effect on berry acidity. Kees showed how vine water status is directly related to cessation of shoot growth. This, I believe, gets to the heart of what we should be looking at in our eastern US growing conditions. Mild water stress leads to earlier shoot growth cessation but how can that be achieved in an environment that experiences about 3 to 4 inches of rain per month - and sometimes much more (we had over 10 inches of rain in September from remnants of Frances, Ivan and Jeanne). Choose low water-holding capacity soils, keep the leaf to fruit ratio at around 12 to 15 m2 of foliage to 1 kg of fruit, increase vine density (maybe), use sod vineyard floor covers to compete with vines for moisture and nutrients, use a restricting rootstock, and use extra canopy management practices to attempt to obtain vine balance when the more proactive methods are inadequate. We are doing many of these things here in VA, but there is more that could be done. Examples - greater attention to soils, evaluation of riparia rootstock under controlled conditions, use of "wall-to-wall" sod in the vineyard, use of root pruning or root-restrictive materials, increased vine density and reduced crop per vine.

Kees' second presentation was an in-depth discussion of the various means of measuring plant and soil water status. At first glance, one might think that the material is overly academic; applicable to research but not practitioners. In reality, most of the techniques described by Kees are widely used in high performance vineyards where the vineyardist wants a precise measure of soil and plant water status. Methods of assessing water stress in vines ranged from the low-tech approach to taking the vine's temperature (by hand or by infra-red thermometer) to use of a pressure chamber (Scholander pressure bomb) to determine leaf water potential, to using carbon (13C) isotope discrimination. Leaves begin to heat above air temperature as stomates close under water stress and transpirational cooling ceases. If leaves are perceptibly warm to the touch, then it is likely that they are under some degree of water stress. The degree of stress can be measured by subjecting the leaves to pressure and measuring the amount of pressure required to push the remaining sap back out of the severed petiole. The amount of pressure, determined in a pressure vessel, is used to determine the tension with which water is held in a leaf - basically, how dried out the leaf is. If the tension is too great, irrigation water is applied. Carbon isotope discrimination measures the proportion of carbon isotopes 13C and 12C in photosynthesis products such as fruit sugar. The proportion of these isotopes in a juice sample can be commercially measured and used to provide a measure of water stress that the vines were subjected to. Given some delays in lab measurement, this seems more of a record of stress rather than a management tool. Take-home message: mild water stress can improve grape and wine quality, particularly for red wines and for vines that have moderate (but not excessive) crop levels. It is important to be able to quantify this stress so as to avoid extremes. Relatively simple and inexpensive techniques are available to monitor both soil and vine water status. We need to adopt these technologies in our vineyard management.

Canopy management options: Andrew Reynolds of Brock University in Ontario provided a capstone discussion on what vineyardists can do to modify the microclimate of grapevines, and how those practices should be adjusted for cool versus warm climates. Andy started with a review of definitions of "vine balance", mentioning some of the same indices described by Phil Freese earlier in the presentation. Techniques to improve fruit exposure and fruit chemistry included selective leaf removal from fruit zones, shoot thinning, and canopy division. Andy's discussion was laced with data he and his students have published from a range of studies under cool climate viticultural conditions. One area that some of the symposium speakers differed on was the question about vine density. Generally, Kees van Leeuwen felt that higher density planting (less fruit per vine) translated to increased fruit and wine quality. Andy's approach, backed-up with his own data, was more permissive: if the vine vigor was great (e.g., greater than 0.3 pounds of cane prunings per foot of canopy), Andy advocated either dividing the canopy or spacing the vines further apart in the row at vineyard establishment. I must admit that I can relate to Andy's approach for two reasons: Andy and I are products of a graduate education where this approach was researched and validated, at least for processing grapes where minimum maturity standards are about 16° Brix fruit. Secondly, our experiences with relatively closely spaced vines (3 to 4 feet in the row) in Virginia have not suggested improved performance. That said, we have not formally evaluated vine density where both in-row and between-row dimensions are adjusted.

Andy also felt that water stress should be avoided, at least for cool climate viticultural regions (such as Ontario). He allowed, however, that mild water stress could be desirable in warm regions. Andy also reviewed findings from Washington State and California that illustrated that high temperatures caused by direct sunlight exposure of fruit can be counter-productive to flavor and aroma production. Again, the comments echoed those made by Zelma Long at the outset of the symposium. Take-home message: Canopy management practices must be used in the appropriate context of the climate in which grapes are being grown. The degree of fruit exposure, for example, should be modified depending upon whether we are trying to keep the fruit relatively cool (as in much of Virginia) or relatively warm (as in Ontario).

I remain indebted to all of the speakers who participated in the Grapes, Wine and Environment Symposium and to the attentive, engaged participants. The impact of the symposium for me was a refreshed sense that we can exert some greater decision-making over vineyard site and varietal matching. We must go beyond simply considering the threats to vines and crop production in our site selection. The role of temperature, humidity, sunlight and their interactions on grape/wine potential should be closely examined under a wide range of site conditions. Greater attention is needed to predicting soil influences on grape and wine potential and possibly ameliorating some of the deficiencies inherent with a soil at an otherwise good to excellent vineyard site. We have greatly progressed in vineyard site and variety selection over the past 20 years and I firmly believe that the viticultural landscape in 2020 will look remarkably different from that of today.

Return to Table of Contents

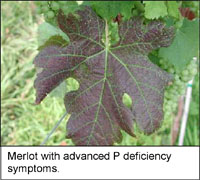

We've seen some evidence of phosphorus deficiency in Virginia vineyards in 2003 and 2004 and a review of symptoms and corrective measures is worthwhile.

Phosphorus is needed for plant metabolism and reproduction‹it's the P of ATP - one of the fundamental currencies of energy used by organisms. Phosphate is also a part of nucleic acids, coenzymes, and phospholipids. In plain-speak, phosphorus is needed for grapevine growth and fruit production and shortfalls of supply can impair grapevine performance.

Phosphorus is mobile in the plant and moves to the growing points. Leaf deficiency symptoms, like those in the accompanying photos, will therefore start on older leaves and move up the shoot as deficiency intensifies. Severe P deficiencies can result in grapevines that have reduced growth with no specific symptoms or shortened internodes. Sometimes, the foliage will weep, and the petioles and veins can be red. Phosphorus deficiency can be confused with leaf roll virus or mite injury, particularly with red-fruited varieties. Vines with long-term P deficiencies have reduced yields. There may be blind buds, or poor or no fruit set, loose clusters, and smaller clusters and berries than usual. Vines deficient in P may take at least a year to show a decline in yield.

Phosphorus is mobile in the plant and moves to the growing points. Leaf deficiency symptoms, like those in the accompanying photos, will therefore start on older leaves and move up the shoot as deficiency intensifies. Severe P deficiencies can result in grapevines that have reduced growth with no specific symptoms or shortened internodes. Sometimes, the foliage will weep, and the petioles and veins can be red. Phosphorus deficiency can be confused with leaf roll virus or mite injury, particularly with red-fruited varieties. Vines with long-term P deficiencies have reduced yields. There may be blind buds, or poor or no fruit set, loose clusters, and smaller clusters and berries than usual. Vines deficient in P may take at least a year to show a decline in yield.

Adequate levels of phosphorous, sometimes reported as phosphate, will depend on the variety. For example, red varieties tend to have higher requirements that white varieties, and Chenin blanc requires more than Chardonnay. In general, we use 20 to 50 ppm in the soil, 0.17% to 0.30% for petioles at full bloom, and 0.14% to 0.30% in late-summer for indicators of P adequacy. By comparison, the photo of the leaf at left came from Merlot vines that revealed only 0.06% P in late-July petioles, with soil P of only 7 ppm in the top 8 inches and 2 ppm in the 10-18-inch profile. Merlot, apparently, is also more likely to express P deficiency symptoms than are certain other varieties (Dan Roberts, pers comm.); Cabernet Sauvignon vines in the same block were relatively free of symptoms.

Frequently, acid soils and P deficiencies go hand in hand. In acid soils (those with a pH less than 5.5) P tends to be very immobile. Furthermore, phosphorous can react with iron (Fe), aluminum (Al), or calcium (Ca), depending on the pH, to form insoluble compounds that are unavailable to the plant. The soil pH in the above-referenced Merlot case ranged from 5.4 to 5.6 - marginally acceptable. In a second vineyard that also exhibited P deficiency during 2004, the soil pH ranged from 4.9 to 5.2 - clearly acidic. Both the pH and the soil P levels need to be examined as both may require adjustment.

Correcting P deficiency: Phosphorus, in the form of phosphate, can be applied anytime, including the dormant season because it doesn't move much in the soil. It should be applied in a band under the drip zone. The band creates concentrations that are high enough to overcome the rapid phosphate fixing (adsorption) that occurs with soils, leaving some of the P available to the plant. Light cultivation after leaf-fall in the fall can assist with moving the P into closer association with vine roots. Elevation of soil pH (if less than 5.5) would be of benefit for a range of reasons that go beyond increased P availability.

Correcting P deficiency: Phosphorus, in the form of phosphate, can be applied anytime, including the dormant season because it doesn't move much in the soil. It should be applied in a band under the drip zone. The band creates concentrations that are high enough to overcome the rapid phosphate fixing (adsorption) that occurs with soils, leaving some of the P available to the plant. Light cultivation after leaf-fall in the fall can assist with moving the P into closer association with vine roots. Elevation of soil pH (if less than 5.5) would be of benefit for a range of reasons that go beyond increased P availability.

Sources: Monoammonium phosphate (MAP) is 48% phosphate (P2O5) and 11% nitrogen, and has an acidic soil reaction. Diammonium phosphate (DAP), which is 46% P2O5 and 18 percent nitrogen, also has an acidic soil reaction. Two sources of phosphate that do not have nitrogen are concentrated superphosphate (also called "triple superphosphate") and superphosphate. Concentrated superphosphate has about 46 percent phosphate (P2O5), and about 87 percent is water soluble and readily available to the plant. Superphosphate has18 to 20 percent P2O5, and about 85 percent of the P2O5 is water soluble.

If nitrogen and potassium are also needed, standard fertilizer mixtures such as 10-10-10 and 20-20-20 can also used as sources of all three nutrients.

Return to Table of Contents

What: This one-day workshop targets those who are exploring winegrape growing opportunities in the mid-Atlantic region. Topics will include economics, site selection, varieties, and vineyard establishment, including materials and methods. Various aspects of established vineyard management (canopy management, pest management, pruning and training, cold injury avoidance, etc.) are discussed at an introductory level. Classroom principles are reinforced with a review of the AHS AREC research vineyard. As with recent years, the workshop will be team-taught by Tony Wolf (Virginia Tech), Joe Fiola (Uni. of MD), and Mark Chien (PSU).

When: Friday, 29 October 2004; 8:00 am - 5:00 pm

Where: AHS, Jr. Agricultural Research and Extension Center, Virginia Tech, Winchester, VA.

Information: Tony Wolf, 540-869-2560 x18 (vitis@vt.edu) or Pat Peacock 869-2560 x11

Registration: Pre-registration is required and registration is limited to first 60 persons: $125 per person, to include morning coffee/danishes, soft-drinks, catered lunch, handouts, and to cover our invited speaker expenses. Check to be made payable to "Virginia Vineyards Association", and mailed to "Grapes", Virginia Tech, 595 Laurel Grove Rd. Winchester, VA 22602. Must be received by 22 Oct 2004 to guarantee lunch. Note: This course fills quickly. Registrants are confirmed registration in the order that registrations are received.

Directions: Virginia Tech's AHS Jr. Agricultural Research and Extension Center (AREC) is located approximately 7 miles southwest of Winchester, VA in Frederick County. From Interstate-81, take the Stephens City exit on the south side of Winchester. Go west into Stephens City (200 yards off of I-81) and proceed straight through traffic light onto Rt 631. Continue west on Rt 631 approximately 3.5 miles. Turn right (north) onto Rt 628 at "T". Go 1.5 miles north on Rt 628 and turn left (west) onto Rt 629. Go 0.8 miles to AREC on left.

Motels: Two suggestions: Holiday Inn Express (540-869-0909) or the Comfort Inn (540-869-6500), both located at I-81 exit # 307 in Stephens City (about 4 miles from the AHS AREC).

B. Virginia Grown Conference (26 - 29 January 2005)

Hold the dates for this meeting which will include the annual meeting of the Virginia Vineyards Association. Location is Holiday Inn Select in Richmond. The viticulture program includes the following topics (partial listing):

Return to Table of Contents

"Viticulture Notes" is a bi-monthly newsletter issued by Dr. Tony K. Wolf, Viticulture Extension Specialist with Virginia Tech's Alson H. Smith, Agricultural Research and Extension Center in Winchester, Virginia. If you would like to receive "Viticulture Notes" as well as Dr. Bruce Zoecklein's "Vinter's Corner" by mail, contact Dr. Wolf at:

Dr. Tony K. Wolf

AHS Agricultural Research and Extension Center

595 Laurel Grove Road

Winchester, VA 22602

or e-mail: vitis@vt.edu

Commercial products are named in this publication for informational purposes only. Virginia Cooperative Extension, Virginia Tech, and Virginia State University do not endorse these products and do not intend discrimination against other products that also may be suitable.

Visit Virginia Cooperative Extension.

Visit Alson H. Smith, Jr., Agricultural Research and Extension Center.